I recently saw a video by American Photonics when looking at their CO2 beam combiners and noticed their lens nozzle based air assist has a very long tube and the nozzle is only ~6mm off the work piece.

I’ve been against the standard lens tube nozzle for air assist because it’s so far from the work material and the exit hole so large it’s just gently blowing the cut by the time it gets to the cut. Consider that while reading and/or watching what’s being tested.

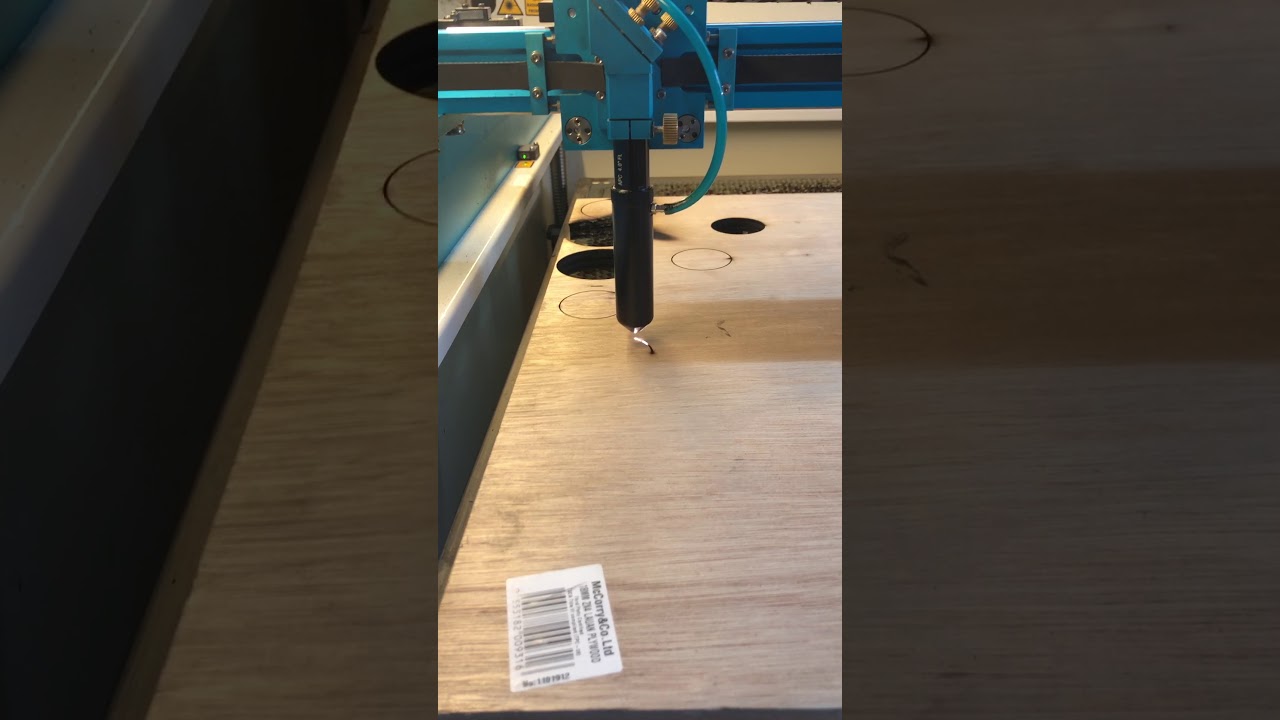

Video showing long tube air assist nozzle: