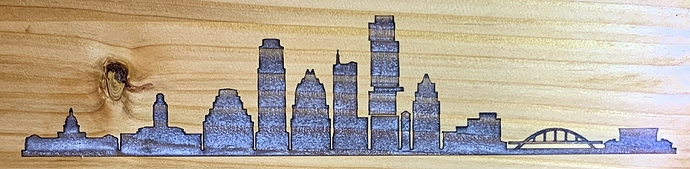

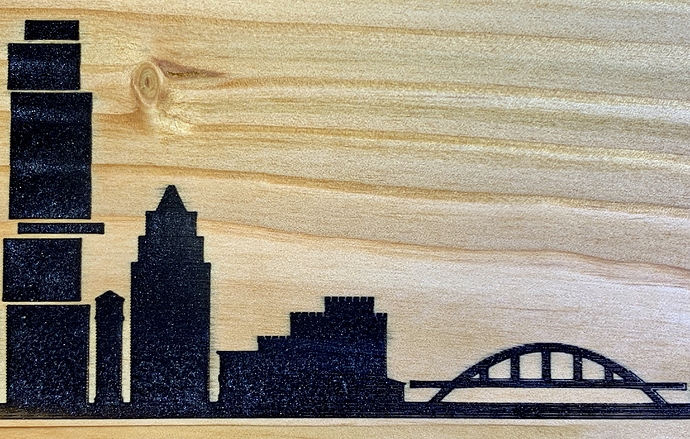

I spent a couple of hours on the phone with Rob the other day. After seeing work done by him and his mentor I just had to learn how it was done. Suffice to say it’s done with a series of shallow cuts each followed by distinct color pour. What I learned was VERY interesting and if other would like to learn how this is done we can do a special Epoxy SIG meeting.

Comment here if that would be of interest to you.