Due to space constraints and always wanting more toys …

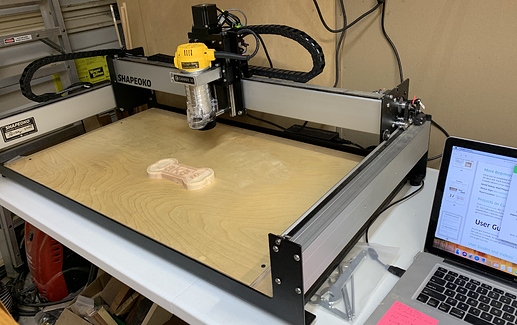

I sold my larger CNC and replaced it with two: Shapeoko 3 and Nomad 883. They sit atop an adjustable height work table underwhich is a wheeled tool cart. While I like that this makes for an efficient use of space and added work surfaces, I just wish I had a larger garage!