Cutting new Zero Clearance quickly that fit!

1 Like

Thanks for posting this Lou-- I have had this on my list to do for my grizzly TS for a while and was wondering how you were able to so accurately “trace” the template (really the curves at the top and bottom) to then draw into a vector for machining. I suppose trial and error would work, but was hoping there was a way to easily get it right. If so, please let me know. Thanks!

I understand your question. I’ve tried this before with little luck. I came up with an easy answer.

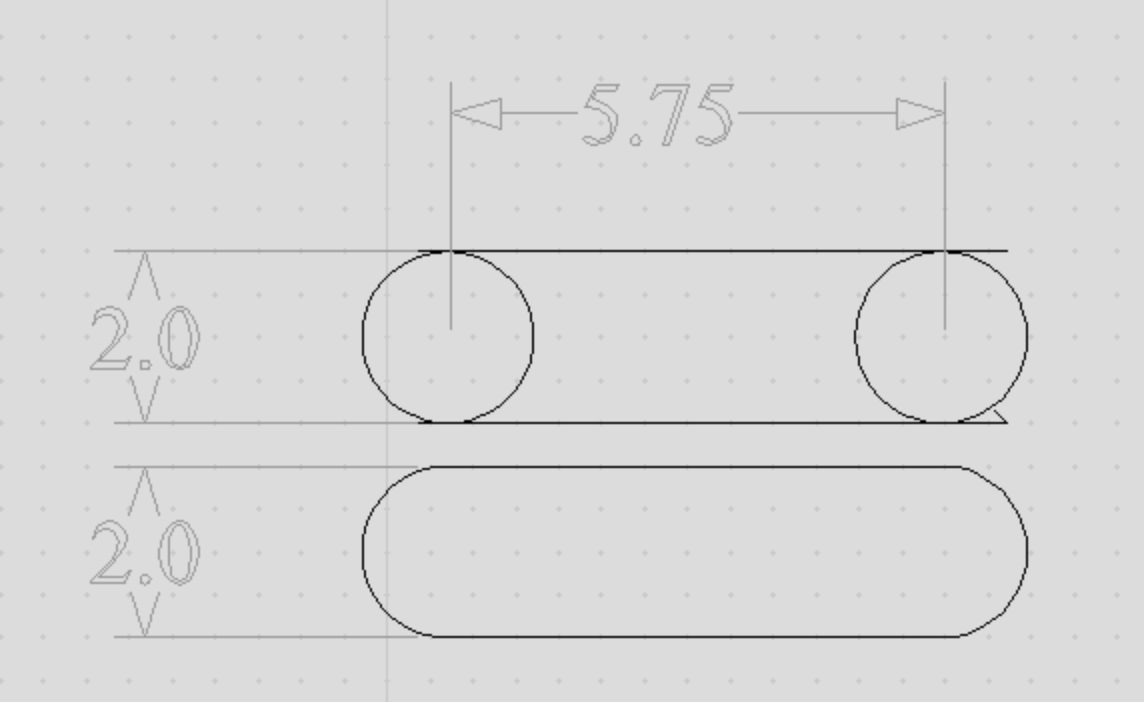

Measure the width of the opening. Draw two lines that distance apart.

Draw a circle at that dimension. Place between lines, copy to the other end, measure to fit (guess).

Trim the waste lines.

Yep, that’s what I was wondering. Perfect, thanks!