Continuing to experiment with 3D models to carve on my CNC. the process of carving is a long one and not for those in a hurry. At least if decent results are desired. If more in a hurry for a plaque or sign then I stay away from 3D models and use vCarving techniques. Results can be very appealing, but they are not the same as actually carving a figure such as an eagle, animal, or scenery. If interested in the process one should experiment with each type of carving to determine what the benefit to time ratio is for them.

As an example, the the Bald Eagle I just carved yesterday took about 3 to 4 hours total for a 6"x6" head. The flying eagle takes about 12 hours to carve. That’s quite a bit of time to tie up your machine and if your the type that doesn’t like to leave you machine unattended while cutting that is a lot of time sitting in the location off your CNC. Then after the carving, dependent on your machine ability, how sharp your bits are, and the way you setup the carve time needs to be set aside for sanding and finish efforts. I do have Vectric Aspire which is very expensive for most hobbyist to invest in, but the work in this post shouldn’t require Aspire because the Eagles that I carved were using models provided by Vectric, I was not creating a model. Stll taking YouTube lessons on how to create models. That will be a post for another day.

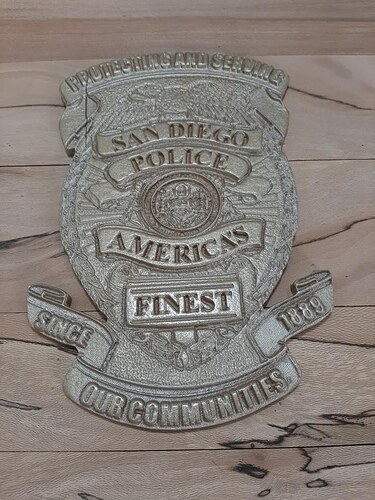

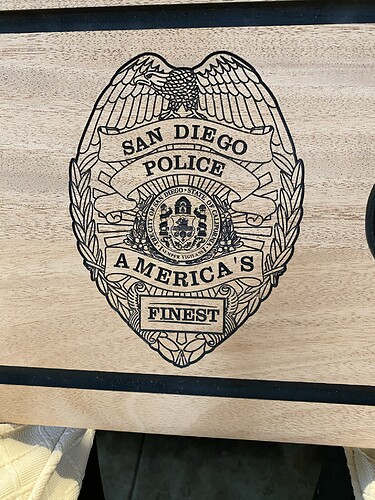

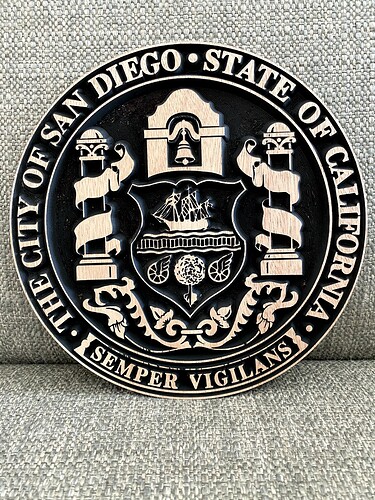

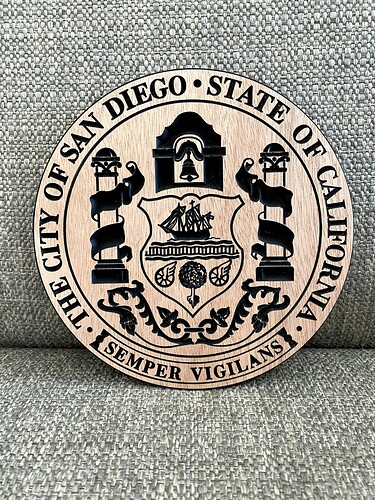

The other methods of getting nice work would be through using simple vCarve toolpaths, highlighting certain aspects with various methods such as stain, paint, etc. I am not good at using this forum text and communication techniques, but will attempt to attach examples of each type of carving to this post.

Carving and using the vCarve software to create plaques, signs, and figurines is quite fun, but can be time consuming. There are tips and tricks that one picks up as he/she goes through the process of experimenting with various carves.

If people are interested, maybe a session with the CNC Sig could spend some time discussing how to import models in vCarve and then set them up for carving. Or, how to actually try and think through how to set a vCarve project. Several people that have been experimenting with these processes could probably share some insights. I know there are multiple SDFWA members that have been experimenting with vCarve and models for many years that could probably really help others through a discussion. I would recommend two different topics. One on setting up a project for vCarving and another on importing models and dhow to setup for carving. If these have already been discussed and are well known I missed these sessions and there may not be a benefit after all.

Any thoughts on these potential discussion topics for the future?