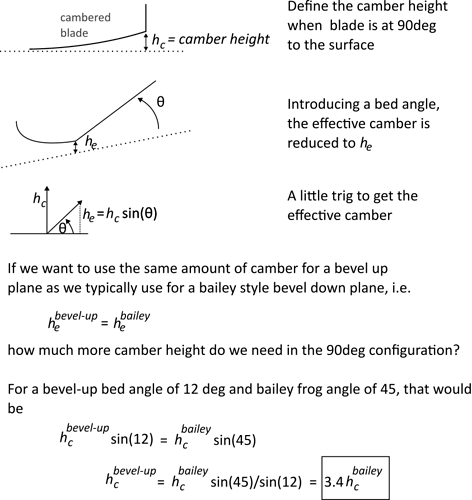

How much more camber do you need on a bevel-up plane to get the same as you’d use on a standard bailey plane (if you use camber)? I think this right, but someone want to check my math?

Yes, you are looking at the math for the complex angle and height. It makes a difference how wide the blade is. Are you planning to use a grinder to start the camber, or just using alternate pressure and then measuring the camber. I would guess shim stock or feeler gauges would indicate the amount of clearance at the two edges. When I worked at Complex Tooling and Molding I could use a micro-optical comparator to measure the curve at any point.

I think making a curved test piece out of metal or plastic with the mathematical curvature described by the equation and laying on the flat side of the plane blade would give good by the eye as to progress as you sharpen.

Let us know how you come out.

Mick C.

I like the idea of a template. But I suppose it could work equally well with a simple line drawn on paper, and hold the paper to the back of the iron.

I haven’t quite figured out how to add the camber yet. Because lie nielsen bevel up irons are so massive, it’s actually quite difficult to do with pressure alone. My plan for the moment is to prop up one side of the blade with a shim, but I haven’t tried yet.

I was trying to follow some tutorials that use camber on a bevel down plane, and since I only have the bevel-up I was trying to estimate how much more camber I’d need to make it function like the guide. I knew it would be more, but was really surprised to see 3.4 times more.

Just a note to the curious, the next Old Tool Swap Meet at Rockler is this Sunday, August 4.