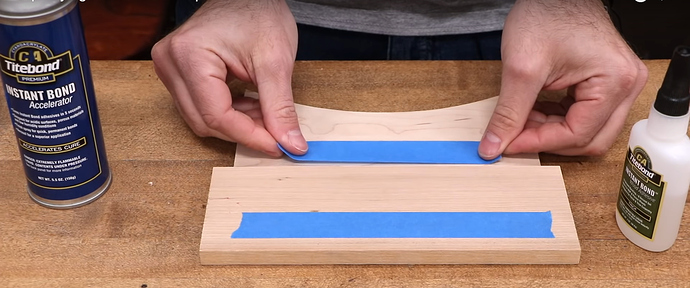

I’ve been through many techniques but I’m in love with Blue Tape and CA Glue with Activator (accelerator). To this day I remember being introduced to this combo.

Howard was presenting it at a Digital Tools SIG meeting and he challenged me. “I’ll put it down and you immediately try to slide it off.” No way could it set up that quickly, I thought, so I accepted the challenge in front of everyone.

Wow, did I look the fool! That hold was not going anywhere. I pushed. I pulled. I slid the bench trying to break that hold. It was strong. Quickly. When I gave up he showed me the next best thing about this technique. It pulls up easily and pulls off cleanly. It’s not good for all hold down but for smaller wood objects it’s really good.