Travis,

In chasing the squeaking and squealing last night, I found nothing relevant or reasonable but questions on the Prusa forum. And I found nothing on YouTube – that will change shortly. Using a solid rod trying to locate the source of the noise kind of failed – an old mechanic’s repair trick. However, it did isolate it to the forward assembly area. Sealed bearing have a really good history – depending on their manufacturer. The Prusa i3 Mk3S+ seems to have really good quality parts so I had confidence in the bearings. The other issues is USUALLY, not ALWAYS, when a sealed bearing fails that is under single line or vector stress the issues appear regardless of the direction of rotation and this squeaking and squealing was when the hotbed was moving forward, not rearward. The noise was not associated with extruder height above the bed or extruder position in relation to the X axis.

My printer gets a lot of use. It averages over 9 hours a day of printing for the last 190+ days, so it has over 1,700 hours of print time. I clean the exposed elements fairly often and every once in a while put one dot of the Prusa lubricant on the rods the carriage rides on.

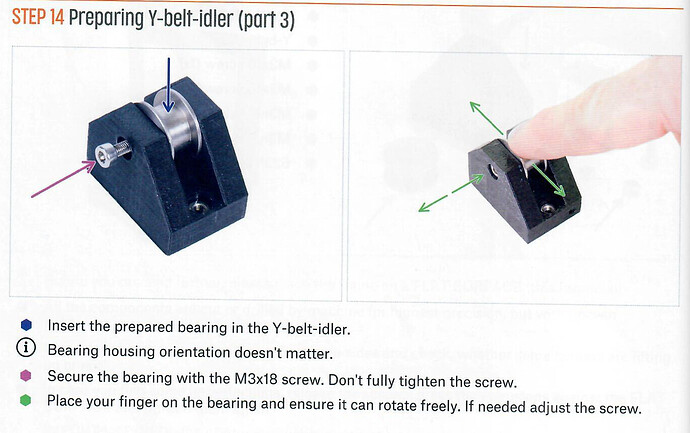

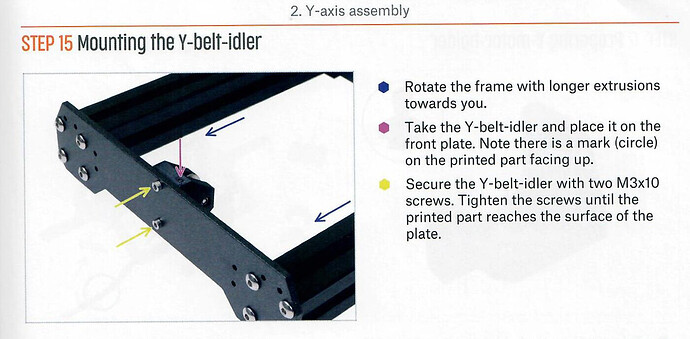

So I got more curious, while waiting for Prusa support to come back with an answer. I released the tension on the Y axis belt and removed the forward bearing from the Y Belt Idler. While it is a SMALL bearing, I could not detect any issue with its rotation. The second element of its rotation is the machine screw going through that bearing. One dot of Prusa lubricant on the insertion side of the bearing and worked the machine screw through it several times to distribute the grease before reassembling the idler on the printer. Then reset the tension on the belt.

At the outset of a 1 hour 15 minute print last night it was still squeaking and squealing but noticeably less. This morning, one 2 hour and 34 minute print complete, a second 1 hour 19 minute print in progress back to its almost quiet printing mode.

So there appeared to be an issue of free rotation with the forward Y axis idler pulley. I suspect that there was too much resistance between the machine screw and the bearing with the bearing being slightly out of exact alignment with the belt pull.

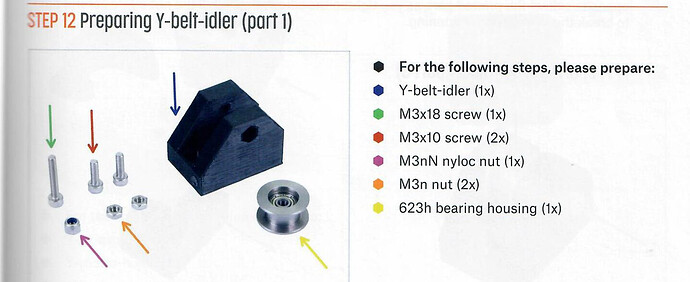

Photos provided, in my assembly manual they are pages 21, 22, and 23, associated with Assembly Steps 12 thru 15.

To answer a question, Why noise while moving forward and not rearward? When the hotbed is moving rearward the tension is on the top of the forward Y axis belt idler pulley. When the hotbed is moving forward the tension is on the bottom of the forward Y axis belt idler pulley. In resolving front end noises in rear wheel drive cars, the owners would complain about noises and vibrations while turning right but not left or going straight, or while turning left but not while turning right or going straight. The axle bearings were under different stresses turning left, or right, or going straight.

Thanks,

Rex

Perform a little maintenance.

Perform a little maintenance.