what is NOT mentioned in the video is that the feature of changing power based on movement speed is firmware specific. Not every controller firmware has laser power compensation based on acceleration/deceleration nor speed. I expect not all GCode based firmware are the same either, ie some might support this capability while others don’t.

From the forum: quote

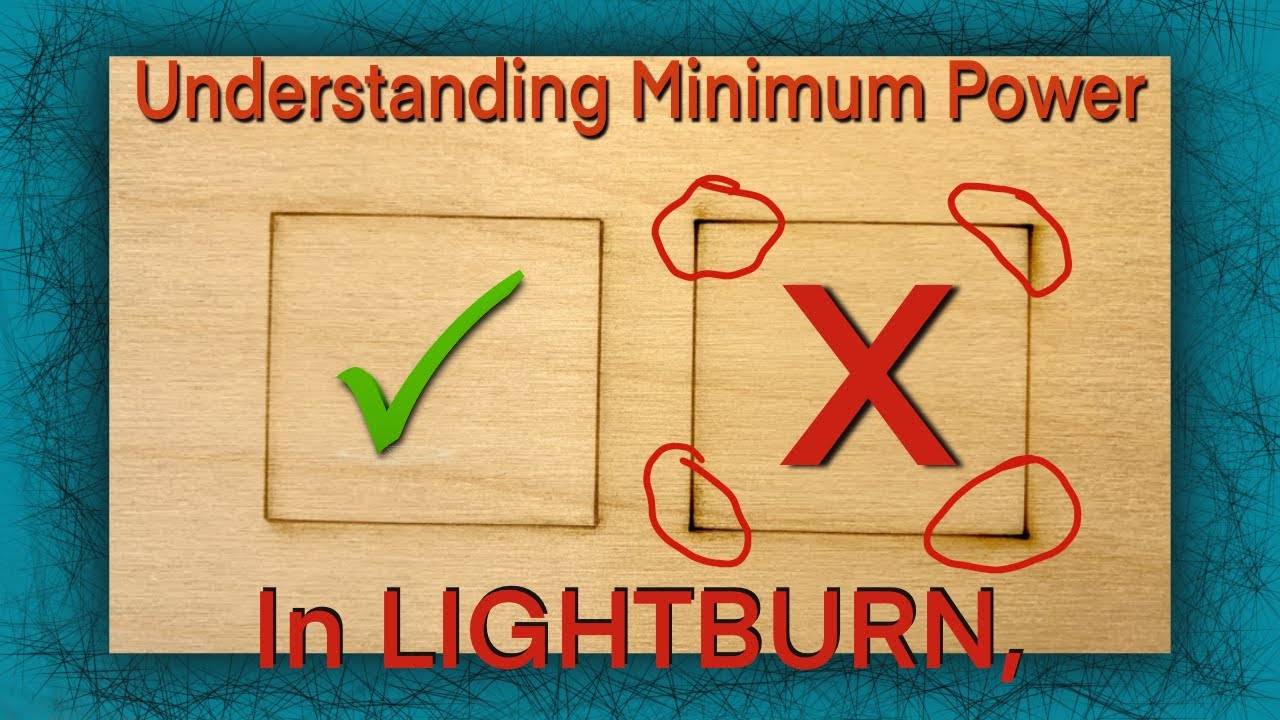

Min Power is used for cuts where the head will be changing directions, slowing down the speeding up again, where you want to not over burn the corners. DSP controllers like the Ruida will ramp, within the range of the Min to Max Power based on the speed the head is traveling. Min Power set too high, over burned corners. Set too low, the laser will not “fire” and will not mark/cut in the corners. The firing point is the ionization point of the glass tube. The bigger the tube, the higher this point, which is why some “heavy cutting” machines include a 2nd, smaller tube for engraving.

LightBurn also uses the Min and Max range when using the ‘Power Scale’ feature.

The min power setting is ignored for everything but grayscale on GCode based devices. The setting for this is in firmware, and can’t be specified per-cut like the high-end DSP controllers do.

end quote

You have my attention Travis! I was quite surprised that this velocity based power level compensation was not part of ever laser firmware. I’m trying to figure out if there are any GCode based firmware/control software which supports this on lasers. Marlin, GRBL and Smoothieware are three common laser firmwares for lasers, CNC machines and 3D printers. GRBL is on the Ortur and Shapeoko to name two many of us know and heard of.

I’ve been working with a developer for running LinuxCNC on 3D printers and will be using the same setup(Raspberry Pi and a $45 3D printer control board) to run my 3040 CNC and my K40. This velocity based control has come up before too… For 3D printing, controlling the extruder motor to slow as the machine slows to make corners will be needed to reduce the little bit of bulging which is currently happening. It is EXACTLY the same thing which is being done in the Ruida and is talked about in the video for the laser power. So once solved for 3D printing, it’ll work for laser cutting too.

LinuxCNC has decades of motion planning design put into it for CNC work and it’s often stated to be the best for GCode Standards support.

For those who don’t know, the minimum percentage power for ionization to take place and hence for the lasers at the Shop to fire, when last measured they were: Green @ 13% and Blue @ 9%.

So cool to dream of a laser with a second tube for low-power work.