Doug,

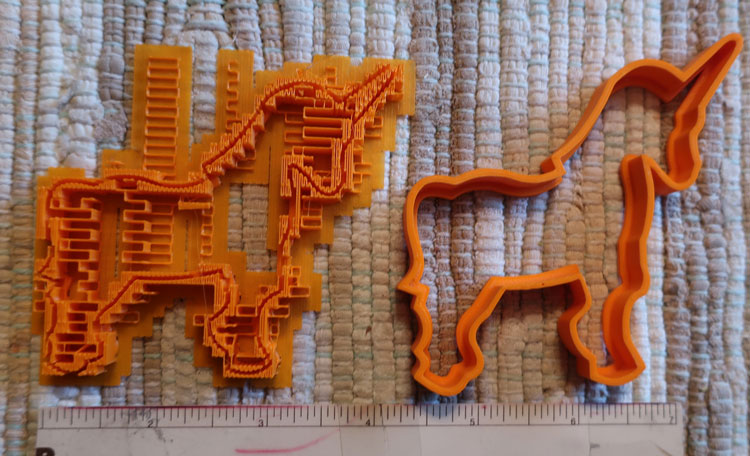

No, I have not removed the skirt. I do not understand why it is there. It seems to be some sort of announcement. “Hi person, I am going to print your desire within this fence.” I see no functional use or requirement for it and figure if I delete it, I will find out the undesirable consequences of that action.

I agree and I save many of my projects as .3mf files just in case. Since my wife is giving me tons of them, and I mean TONS of them, I separate them into an active directory and a history directory. I have burned through three full spools of filament and have four more with more than 50% consumed and a couple more well on the way all since mid-late August 2021.

I had to downscale one of my projects as the skirt was on or over the print area border as I remember. I chose not to remove the skirt as I do not understand its function. It printed at 95%. I am amazed how much printing time changes with even a 5% reduction in size on a large print. Yes, I understand why.

That big fat “How am I doing line” in the front left is interesting. I have not watched it or timed it but it does seem that the extruder movement is slower than the normal print movement at the start of that line and does increase speed as it nears the end. The line is wider at the start and then tapers. I assume, guess, Z height does not change during this print so it is either extruder movement rate or flow rate causing the difference in the line. Interesting. Some claim it is a Z height check. Not sure, however, if I were programming a Z height verification process, I would keep extruder movement and flow rate consistent during the test strip. I use the skirt for a Z height check. More accurate in my opinion.

Doug, my parents wanted a puppy, I came out so they named me Rex. I have lived the early years of my life in the dog house. Then I got married, thinking life could get better. Then I had three daughters and no sons. From Day 1 of my life it seems to be headed downhill. Each day I pray I hit rock bottom to stop the descent but the fall just seems to continue.

(June 17, 2022, we will be at Disneyland celebrating our 50th wedding anniversary. I have learned if I do not laugh every once in a while life is really dull. A photo from a long time ago. Yes, I got very lucky when I met Joyce October 5, 1970. I remember the date and approximate time - 5 p.m. because of a job change.)

Thanks,

Rex

I know the Dog House well.

I know the Dog House well.