I have a CNC project idea for when I finally get my end mills from china… The ones I plan on breaking a bunch when I get started and ordered from Bangood over a month ago and are being shipped by boat.

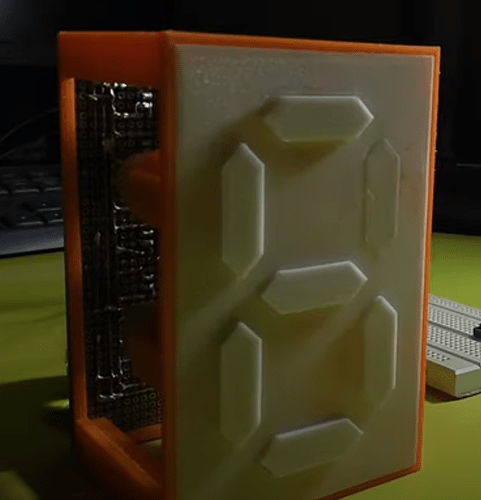

Goes something like what this guy did with 3D printed parts to make an 7 segment display( digital clock). But instead of plastic parts for the face and for the segments which don’t fit well together, How about create inlays which are glued to plastic parts and moved by cheap servo motors behind a nice wooden face. This way, when the segments are pulled into place they are almost invisible. Cheap $1-2 servos move the segments in/out. My thought was to get a piece of wood for a single 8 segment display, saw 1/4 inch off one face giving you 2 pieced of wood with the grain very closely matching. Mill the 7 segments into the big chunk first by inlay process and then clearing a rectangular pocket inside the inlay area. Next engrave out the inlay segments in the thin part so visible wood grain is matching closely and they can be separated and glued to 3D printed parts or small wooden parts which are attached to servo horns.

If ‘doable’ I think it could make a pretty great looking digital clock. There’s a bunch of things like the PCA9685 chip/board which can drive 16 servo motors from one control signal(I2C) from an ESP8266/32 or rPi(ZW).