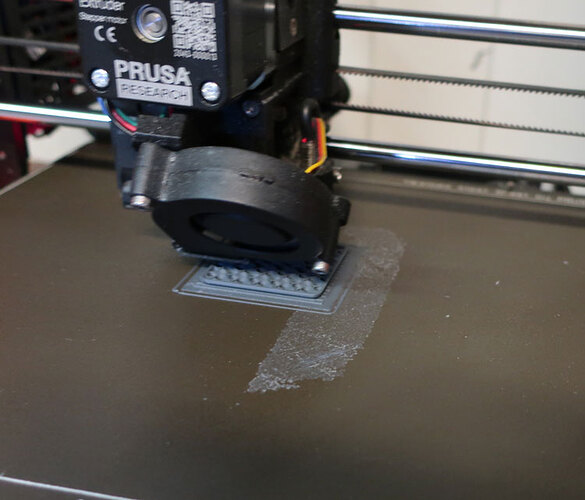

I am making a GPS mount and cellphone mount for my Subaru Forester. Kind of fun. Designed in Fusion 360 for the 3D printable parts, sheet metal work with some brass for the majority of it. In reading some auto and trailbike type GPS mounts in Thingiverse they recommended ABS filament as PLA filament evidently sags after heat saturation like that of a closed car. I am having problems getting good, clean removal of the print from the heat bed after printing. There is a shadow of filament left that is simply hard to impossible to remove.

While the first four or five prints came off with a bit of work, alcohol, dish soap, hot water, this last one is stubborn. So stubborn that I decided to print over it.

Suggestions (besides avoid ABS).

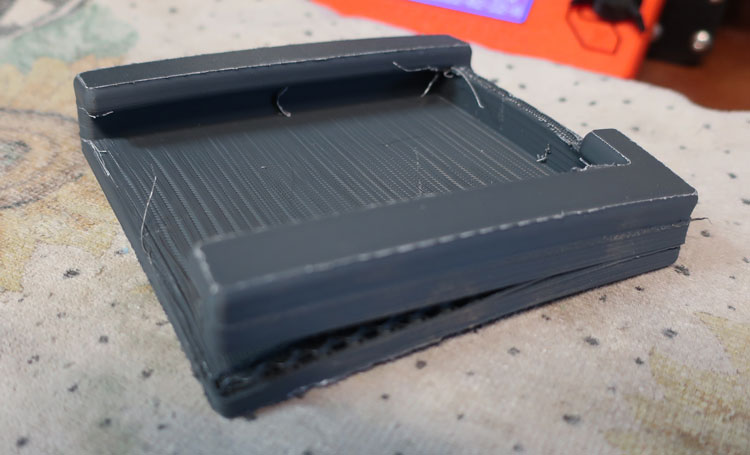

Comment on ABS in my Prusa i3 Mk3S+ printer, just about every single print, and some are in the 4+ hour range, warps during printing. While I wanted to print this project as one piece, over 11 hours, it is now four pieces, a 106 mm x 120 mm x 9 mm bed that warped, kind of surprised the Prusa reset after a crash as the nozzle hit the print and finished the print. One side that is about 45 mm x 34 x 120 mm x 25 mm, a second side that is about 23 mm x 120 mm x 25 mm and only one of those printed without warping.

First, major failure attached. All the supports have been removed. Due to design the photo has it upside-down from the print.

Thanks,

Rex