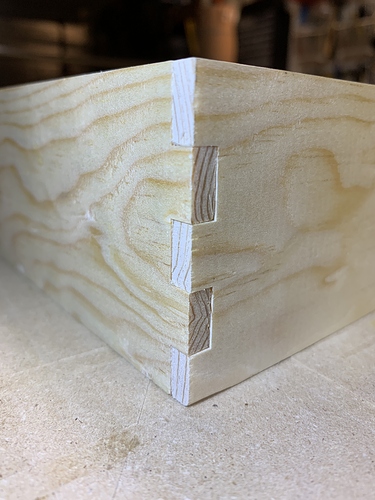

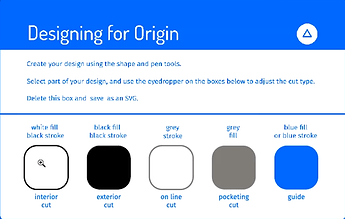

My Origin does things I can’t do otherwise. Precision joinery is child’s play making simple to exotic mortise and tenon joints a snap. Carving recessesses for inlays and cutting perfect-fit inserts is easy. Milling on finished products such as cabinet tops, floors, etc is possible. Cutting large projects (4’x8’ ply for instance) are possible because there are no cutting area constraints. Also, this “CNC” can be taken anywhere to work its magic as it’s no larger than a big plunge router. Yes, I remain a fan.

That said, you have to really like these concepts and want to do them to justify: 1) the cost of the Origin, 2) the cost of the Workstation (a key feature), and 3) the time spent to learn a completely different workflow.

I justified the purchase because I have done projects that required a 4’x8’ bed and have no room for such a large CNC nor access to a large-bed CNC. Also, I’m a digital tools fan and had been watching the Origin since it was a prototype. I skipped the entire 1.0 product and only jumped in when 2.0 came out and I could make a workstation, the project that inspired Shaper to produce the Workstation.

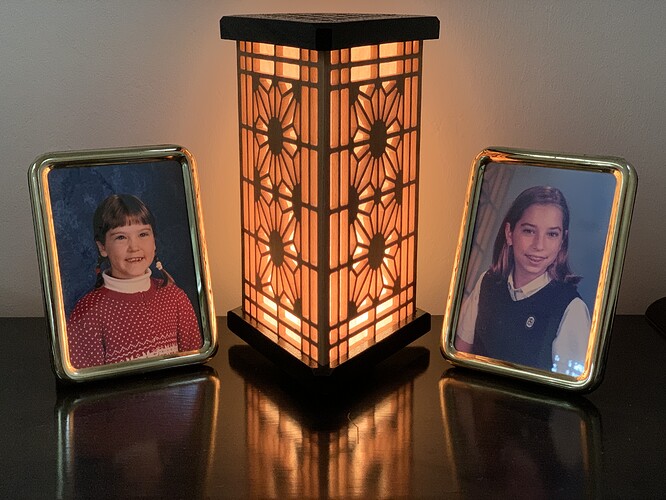

Lately I’ve been enjoying projects from their open crowdsource community called the Shaper Hub and their professional designs Premium Projects. You can see one example below, it’s my three-sided version of their Lattice Lamp.

Want to know more? Check out the Shaper Sessions.

I watch these each Thursday at 4:00, evidence of my interest.

The Origin is a whole new category of tool so there’s much potential.

Cheers, Travis

Daughter pictures are from 20 years ago.