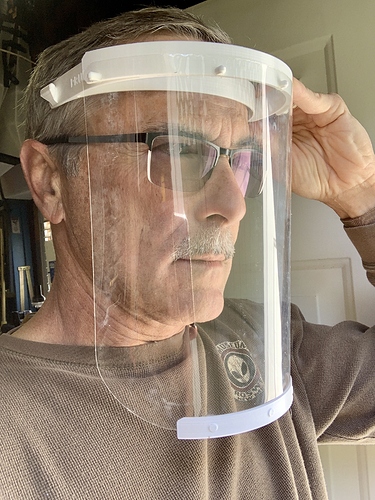

So I spent a great deal of time today trying to print the prusa shield headband with pla.

Went through tons of bed leveling, temperature settings, recalled that I set up the incubator and so had increased humidity in the room, so switched out the filament…

Finally finally, change the nozzle? I’ve never had a clogged nozzle (since I stopped using glitter filament with my old printer). That solved it! I’m back in the game.

I have to say after about 6 months of consistent daily use, this was the first trouble I had with the Ender. I’m really happy I got it. Meanwhile my home-made delta printer is just sitting there looking like a pretty robot that doesn’t do anything.  I should get her working again someday. She was really fun to watch.

I should get her working again someday. She was really fun to watch.

Susan

Always buy the spare parts, you will need them someday.