I want to cut out a shape in 1.5" depth of wood. Many common end mill bits have a cut depth of 3/4" or maybe 1". Would a cut depth shallower than the depth of wood work when gradually cutting to full depth? Or would there end up being a problem with the smooth part of the shank starts to hit the already cut part of the wood?

You would need a bit with a longer cut distance. They have them but they get a little more expensive. The problem with a short bit if you don’t fully get it in the collet, you could have some issues. I would be more concerned with the collet hitting the wood trying to cut that deep with the wrong size bit, IMHO

Jeff,

I would highly recommend that you not try using a bit with a cutting depth less than that which is needed for the depth of the cut. The concern is rubbing of the bit against the edge with the non-cutting surface but more importantly the amount of bit in the collet. To get the extra depth from a shorter bit, will require you to not properly insert the bit deep enough into the collet. Need to purchase a longer bit, they are available.

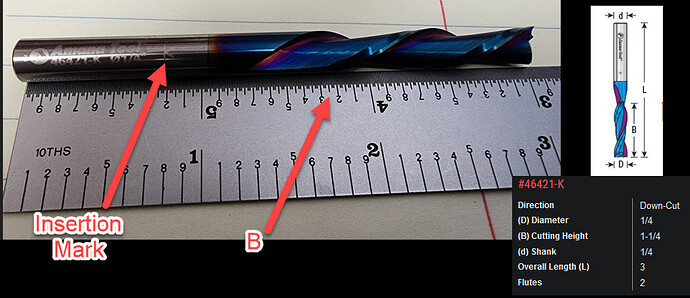

With respect to my very experienced colleagues I may in some cases do this occasionally even though it is not best practice. Sometimes you just don’t have a lot of other options on 6/4 and thicker material. Looking at the example Amana 46421 bit I would not have a problem going .25 over the CH (B) or even a little bit more. Things I would consider in this situation are:

- How many passes will be “rubbing” on the surface of the bit? More than 1 - 2 would be a red flag.

- Is the bit deep enough in the collet? I use mainly Amana so this is clearly marked. Note that even with this I still can (and usually do) mount it deeper and still exceed the 1 1/4 CH of the bit if need be.

- If you do this make sure to double check your lowest Z travel to make sure that the collet doesn’t hit your workpiece. I do this before every cut even if not violating the DOC of the bit. Don’t ask me why.

- It goes without saying but if you need to do this a lot get the larger DOC bit.

Hope this helps!

Perry

I ended up using a 1/4" endmill I found in the drawer. The cut length was either 1" or 1.25" and it worked great. Thanks

Your pictures and discussions made the points much better than I did. Thank you for your thorough answer.