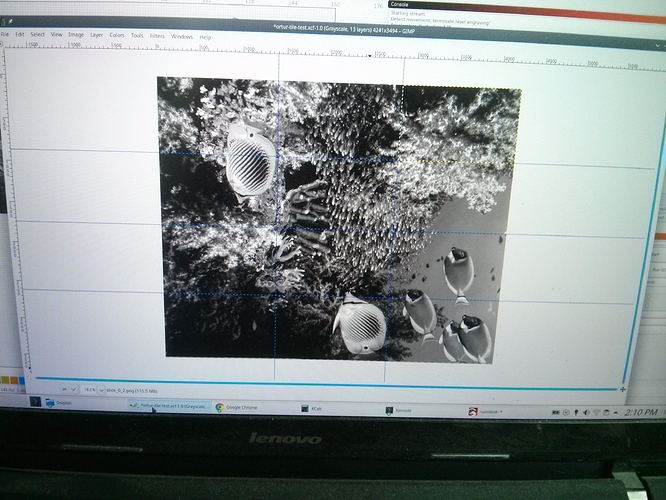

I had some big flat boxes and thought they a good test platform. So I scanned in a large calendar, trying its B&W mode at 300DPI. I then opened the TIFF file in the free GIMP photographic editing software to cleaned up the seams. To make the tiles I found I could setup “guides”(found under Image menu) and then setup guides at 25,50,75 percent Horizontal and 33 and 67 percent Vertically. Using the Web->slice filter produced the 12 images saved to disk.

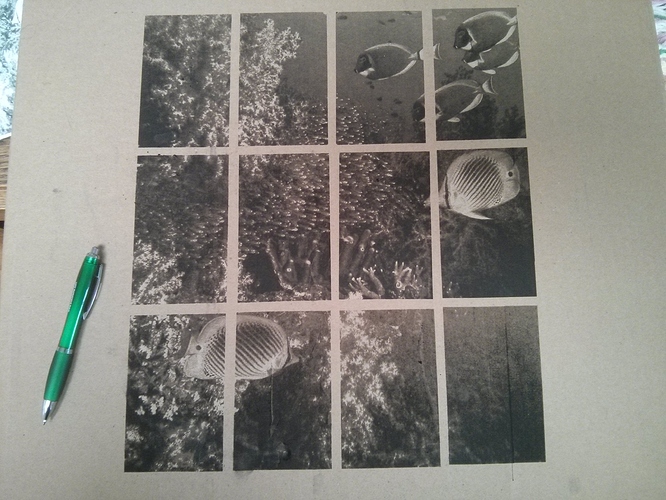

At 35mm/s and 35% power it looks good on cardboard.

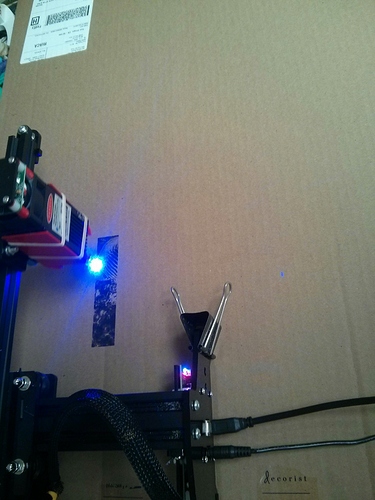

Focus was set to the working surface so the Ortur is sitting right on the etching material/box.

Image 0_0.png