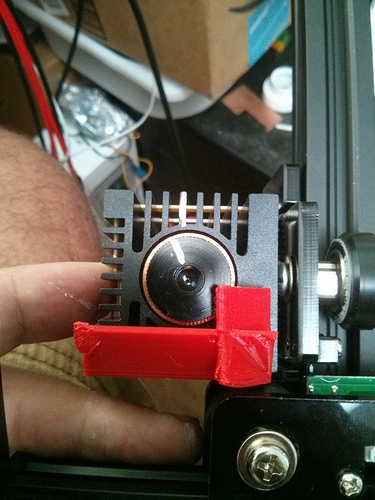

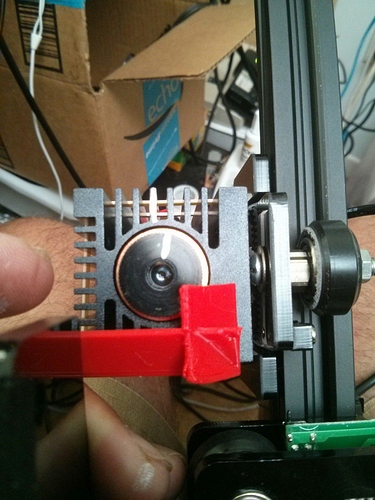

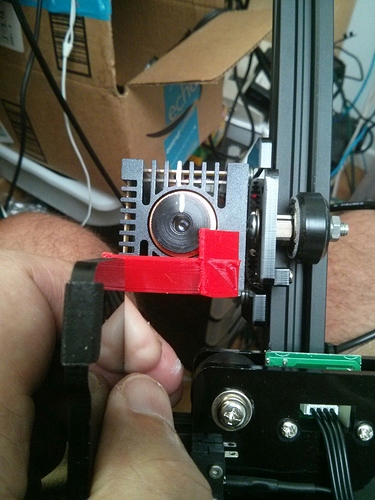

I think you are in luck since I don’t see the bearing housing moving so it looks like it’s just the pressed on soft wheel part. I would take the thing off, find a hard flat surface and then try to straighten it on the bearing.

Maybe in F360:

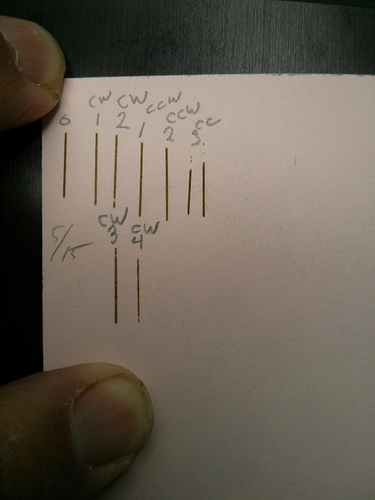

- make cm thick block with a slight recess for the bearing(notice it’s slightly proud of the rubber on both sides ). Maybe 1mm deep. Also create a 5mm hole through the center.

- 3d print this and put the bearing/wheel in it and using the screw and nut tighten it so it moves the rubber flush with the bearing on one side.

- now flip it over and do it again but now just move it so the bearing is slightly proud of the rubber on both sides.

Should be straight at this point.