I did a quick test cut in the shop today that I think you all will appreciate.

I even got to use Travis’ favorite tool! Note: this was done on the Nova 35.

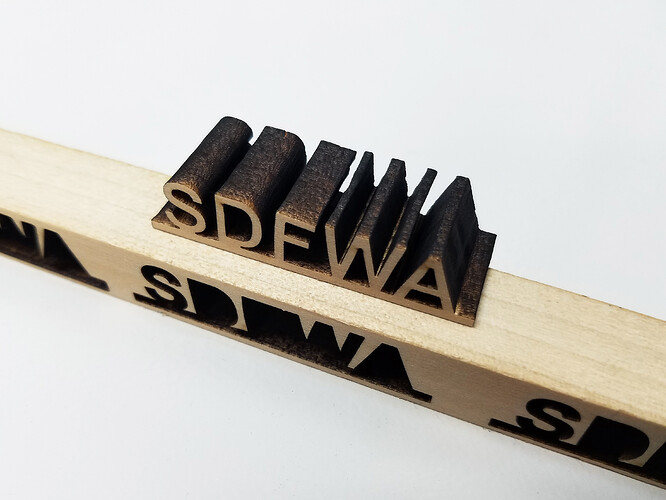

Laser cut “SDFWA”:

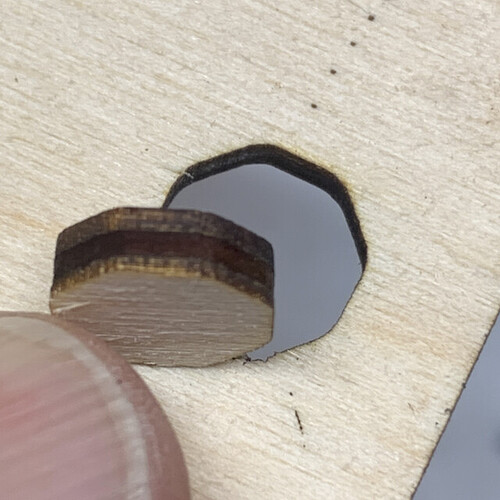

Laser cut “SDFWA” measurement:

Details:

- Machine: Nova 35

- Speed: 5 mm/s

- Max Power: 100%

- Min Power: 100%

- Line Interval: 0.05 mm

- Passes: 1

- Material: Maple (solid)

- Material thickness: 18.24 mm (0.72 in)

- Focus: ~1 mm below surface

- Laser tube power: 100 W

- Lens focal length: 2 in

On my first try, I set the focus to ~4 mm below the surface. This resulted in a noticeably worse cut with a significant kerf width on the top surface. Changing the focus to be ~1 mm below the surface resulted in an incredible cut. The sides remain straight all the way to the bottom surface. I didn’t expect it to be that good so far out of focus. I suspect that the power density of the laser beam is much higher in the very center so it is still useful for cutting even when the overall beam width (lower power density) is quite spread out. Sliding the “SDFWA” out of the wood block reminded me of wire EDM due to the tight fit.

I suspect that even thicker wood could be cut with ease. More testing is required ![]()