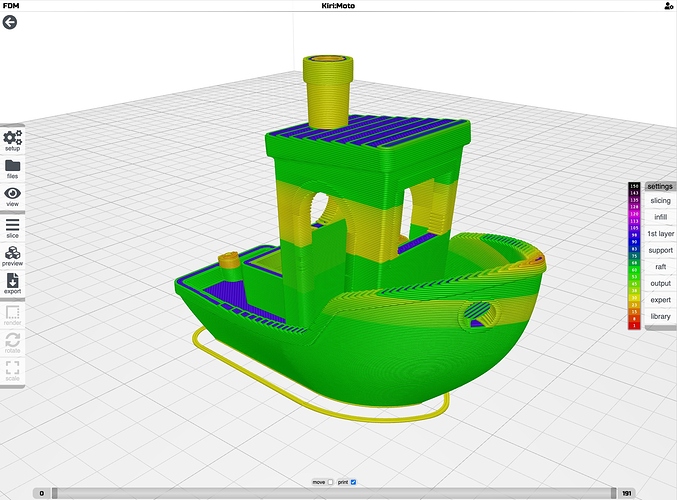

I’ve only used Kiri:Moto a couple times so far but as a very rookie CNCer I found it pretty easy to use to generate toolpaths. I’ve met the developer also and he’s not only a very skilled software developer but he’s also a user of his software and enjoys making it better and easier to use and it’s free for anyone to use.

He’s asking for input on a few changes he’s making and I thought it would be valuable if any of you CNC regulars had input into the proposed changes. It might help taking a quick look at Kiri:Moto and since it is a web browser based tool you can by just going to https://grid.space/ and then clicking the Kiri:Moto logo at the top. You can even upload a design and get a toolpath back after setting up the firmware, defiining some tools and selecting which toolpath ops you want(rough, finish, outline, drill, etc)

Here are his proposed feature changes:

I’d like to get feedback on a few planned changes and also open the floor to suggestions for new or improved features.

- limit roughing to inside. no more cutout in roughing.

- expand outline to inside, outside, or both. not just both or inside.

- tabs would only be active for outlines.

- outlines in outside-only mode = cutouts

- split out surfacing from an implied roughing operation

- add a “flats” operation to clear flat areas separate from roughing. or combine with surfacing as an option.

- add new strategies for roughing operations. the offsetting works OK, but I have others in mind that might be faster and cause less tool wear.

I’m in the process of looking at adding drag-knife support in laser mode. But I’m on the fence. It could also fit in CAM mode. However, that would require adding a “knife” mill type and that would complicate things. Thoughts?