Normally YES, but not always.

I made some some small wooden signs I sell at a local craft store. In the past I used a white poly board, painted it black and v carved it.

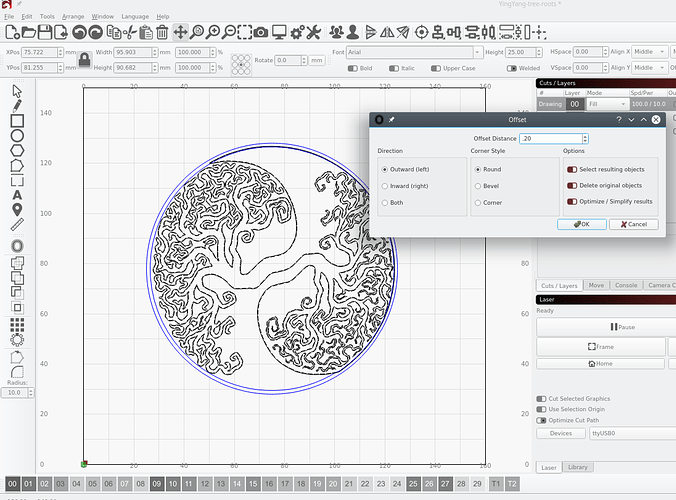

Since I got my Ortur I decided to use wood and laser it. The problem I had was the lines on the text were too fine and therefore not easy to read. So I started to play around with the focal length. For me I decreased the focus distance by about 1/4 inch. These caused the beam to be be slightly wider and burn darker,

.