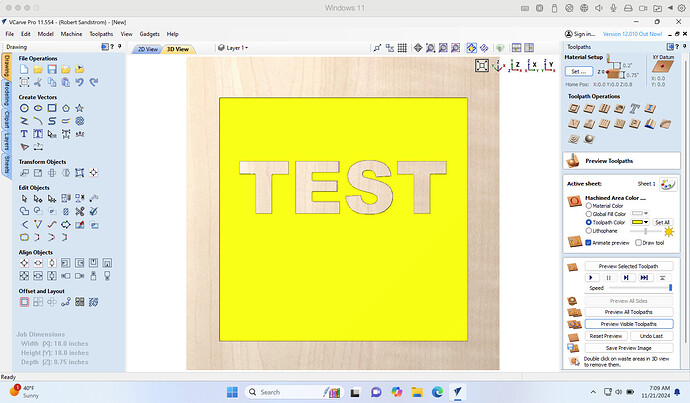

I’m looking to create a logo sign that is around 18"x18". The sign will have 3 layers of text/objects, kind of like a text-on-text sign. For the top and middle layers there are a log of around that needs to be cleared out. Because of this my design using a .25 EM shows to take a couple of hours just for that pass.

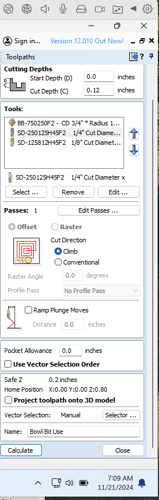

So, I’m thinking I could use a flattening bit to mill out this area. I have defined my flattening bit as a 1" end mill. The cutting blades are .25 in so I currently have the pass depth set to .12". I have defined a pocket tool path with this 1" EM and a .25" EM. The middle layer I have the same plus a .125" EM.

With my current VCarve Pro project using the 1" EM I have cut the estimated time from about 6+ hrs to about 2.5 hrs.

Does anyone have any experience using a flattening bit as an end mill. Are there adjustments I should make to my tool definitions or any gotchas to be aware of. I have had limited time in the shop (because of my own schedules) and the shop CNCs are the only ones I have access to. So I’m trying to maximize productivity while in the shop. But I can play with some practice pieces.