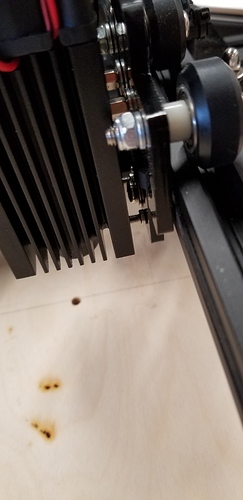

I noticed that the laser is not attached very well to the X axis arm. It is somewhat flexible in the Y direction and was visually not perpendicular to plane of the wood. I put a washer between the each of the laser’s hex standoffs and the black plastic adjusting mounting plate (I bought longer screws). This helped stiffen up the flex in the Y direction considerably. I also put in two jack screws into the laser and backed them out until they just started to contact the black plastic adjusting mounting plate. This put a little preload into the laser mounting resulting in a more rigid attachment (four points of contact now). I believe there could have been some Y axis vibration under the right conditions but these two tweaks will reduce that.

3 Likes