Okay, update on the update. Late night work and posting compounded to really screw things up. And I need to clarify X and Y axis of the Ortur. (Thanks for the additional input Doug.)

When I got the Ortur 180 x 180 several months ago I put it together and it worked fine, no issues. I installed it on ½” piece of plywood and etched a grid on the plywood as a reference. No issues and nice output on some sample text. Then, with French cleats – suggestion or comment from someone on the Forum, it went up the shop wall for other projects and missions that had priority. Having the Ortur on a ½” piece of plywood that is approximately 23” x 15” gives it a pretty stable base.

Issues were interacting and with the help of numerous Forum members, especially Doug LaRue, I will step you through my issues with the Ortur and their outcomes.

I updated the firmware to 1.40 in the middle of this process. Ortur provided good guidance and there were no issues.

There are tons of videos on YouTube about LightBurn and I watched, learned, from many of them. And SDFWA has a good video on the Ortur and I watched it in its entirety once and started it several times. Maybe this is a repeat of some of their materials.

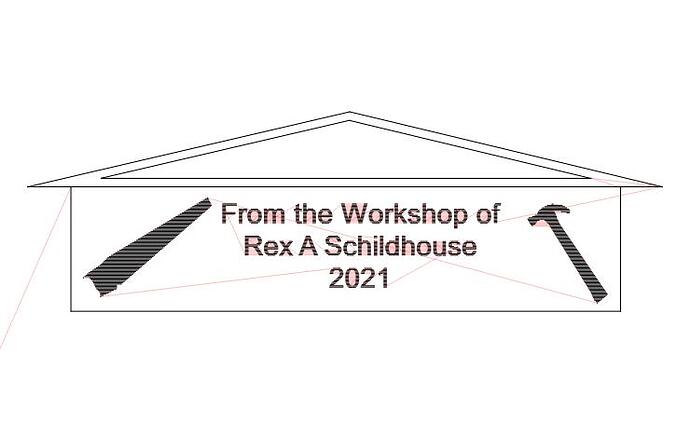

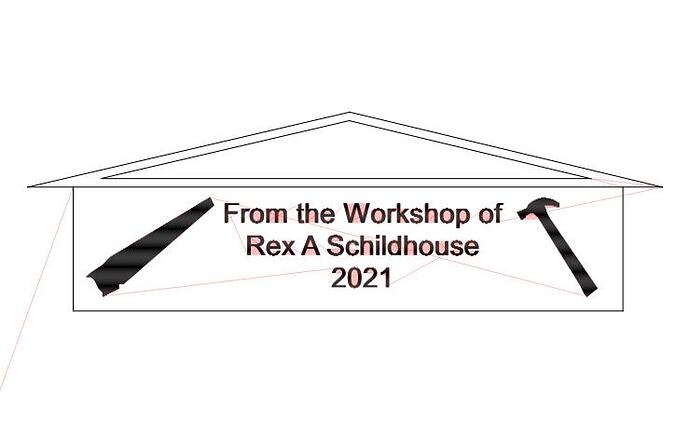

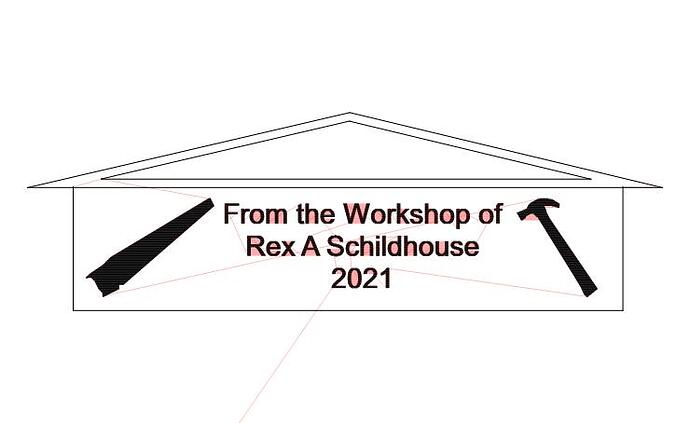

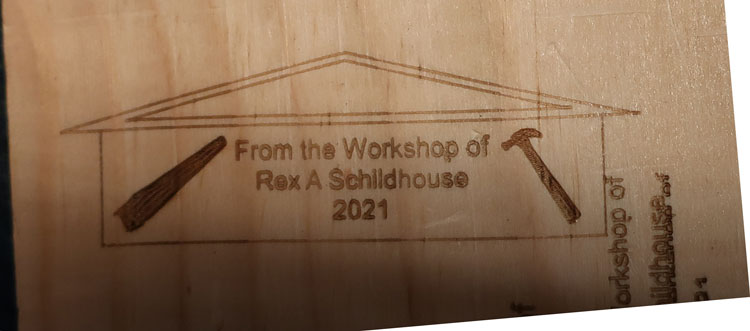

When I had time I added LightBurn to my software library and brought the Ortur out of hibernation. And it had issues. Here is a copy of what LightBurn had as a preview.

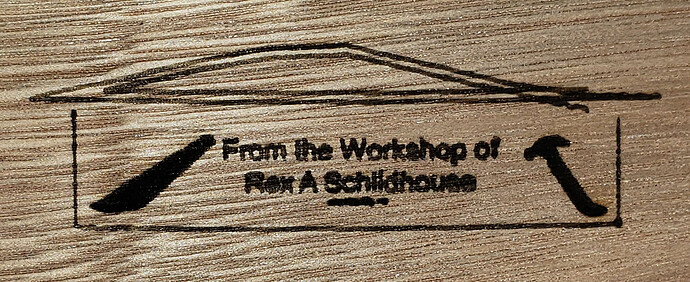

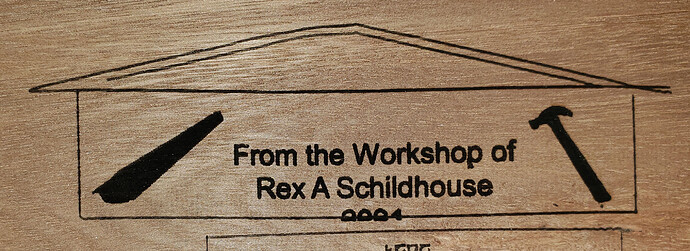

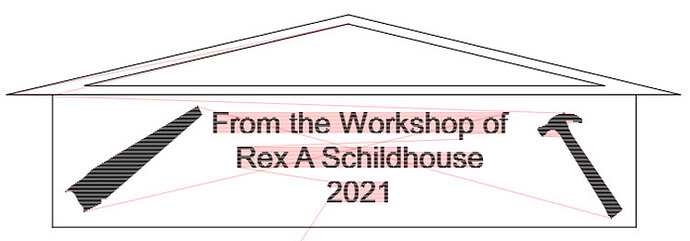

Here is what the Ortur actually produced. The lines of the roof are bad, the date is bad, etc.

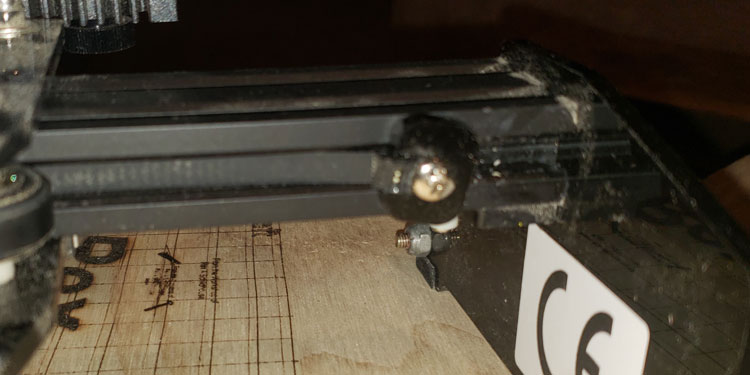

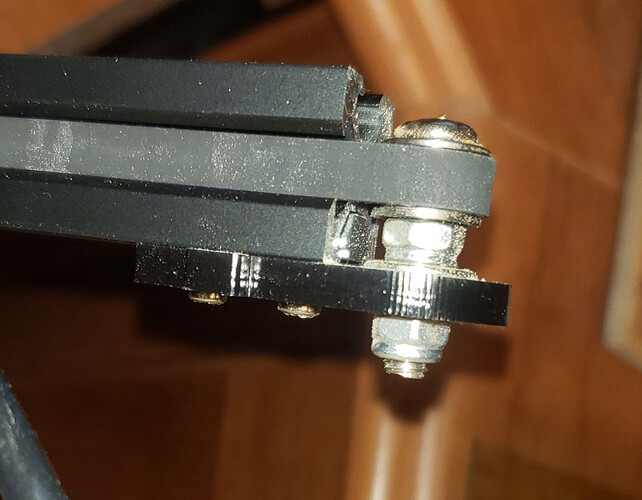

And with sample, simple text, the Ortur was performing well. So I was confused. Searching the Internet provided no solutions so I went to the Forum and got some really good comments and I started working on it. Knowing one thing and realizing that one thing are not the same. In the process of solving the issues I adjusted the tension of the Y axis by removing this screw, pulling the belt through 1/8” or so, and reinstalling it. That addressed the Y axis belt “stretch” that probably occurred while the Ortur was hanging in the workshop over the summer. The photo is before tensioning.

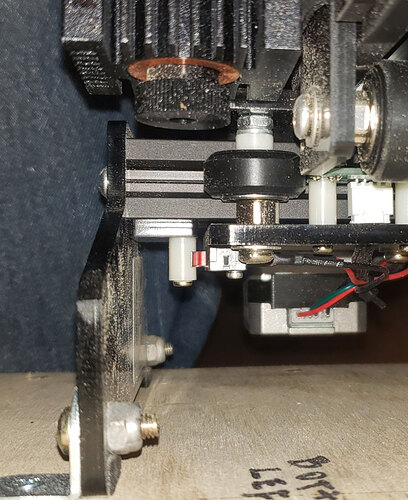

Then I tightened this belt, thinking this belt had something to do with the Y axis, it was late at night and I was moving from frustration to elation. No, this pulley at the end of the arm is only for the X axis belt. Now it is snug.

To get to those two screws I had to remove the Ortur from its deck. When I did that I realized there was a switch underneath. With an electronics background, got curious. One of the issues was that on a “Home” command the Ortur went to home nice and quietly, at other times it tried to motor through Home for way too long. The post / contact was inconsistent so the first effort was to bend the tab to ensure activation. Not consistent. Doug LaRue said that the post on his (non Ortur) laser was adjustable. So I tried with the Ortur. Moved it a bit, not much. Combination now is that I have consistent contact between the Y limit switch and the post. I think Doug’s comments about swapping hardware is good, however, at the moment, “If it ain’t broke, don’t try to fix it.” (If it ain’t broke, take it apart so it is.)

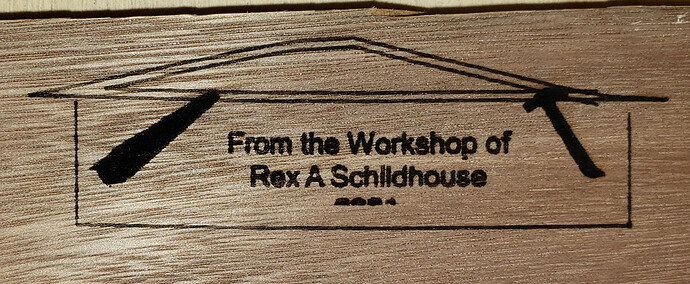

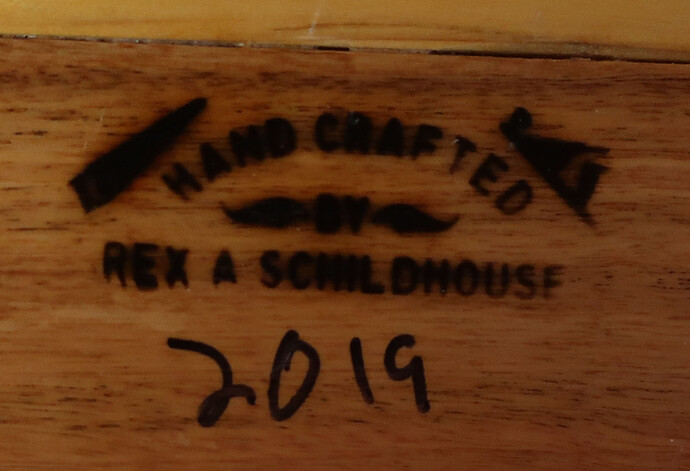

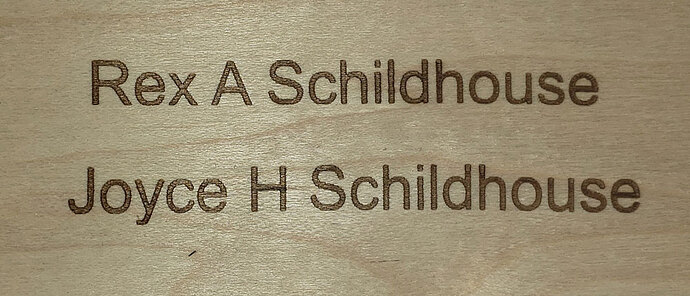

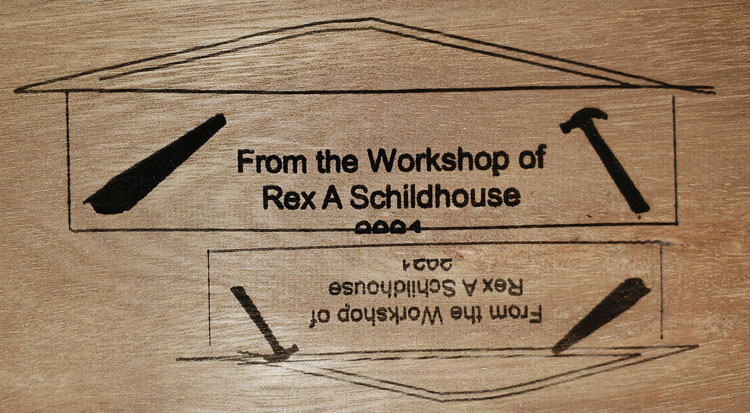

Back to running some test burns of my 2”, 3”, and 4” brands. All came out really well.

Did some test burns of text and other figures, all came out really nice. The Ortur is up and running for what I want it for primarily – to brand my toys and work instead of using my many years old electric branding iron which takes 15+ minutes to heat up and consumes power like a Naval Aviator devours steak at an all you can eat buffet. (What is a salad at a prime rib dinner? Interference, a delaying action.)

Impressed with the precision of the burns of the little Ortur, which was purchased based on recommendations from the SDFWA Forum.

Thanks to the Forum members for the help,

Rex