The box arrived.

You want to start using your new laser.

Invariably there are issues; here’s where you get answers.

Richard and I were talking about Ortur setup last night …

The repository for documentation, drivers and configuration info is here.

You’ll want to install the Windows Virtual COM Port driver. Getting a consistent connection without this is iffy. You can download the drivers in 2.1 here.

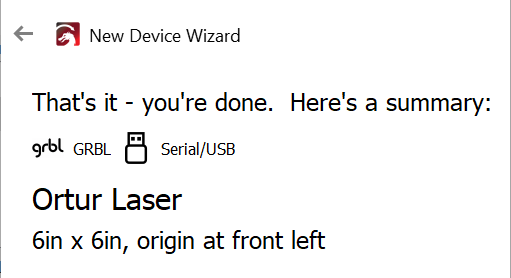

You’ll want to add the Ortur Laser to your LightBurn Devices list. The step-by-step instructions for how to do that can be seen here.

LightBurn support has improved in the latest firmware so you’ll want to update it. The process was remarkably easy to do so don’t feel intimidated. You can learn the process and download the file here.

My setup in LightBurn looks like this:

I agree with those steps but I wasn’t able to get the lightburn to communicate well with the laser until the one time I got LaserGRBL from here: https://www.dropbox.com/s/w1yu3hpw6e5rxs2/Manual.zip?dl=0 installed and working. Why it worked after multiple tries I don’t know. I just observed that after LaserGRBL worked the LB started to connect ok and I have not had to re-run LaserGRBL.

I also liked the suggestion of copying the gcode from the laser but I’m not clear on how I reload it should the need arise.

It is also not clear what type of laser goggles I should aquire to have a spare set for visitors. Anyone know? I’ll also ask Ortur…

The key is to have a pair of glasses block the frequency the laser emits.

Light from our laser is 445 ± 5nm so glasses that block that are fine.

Here’s a quick search result on Amazon of compliant glasses.

https://www.amazon.com/s?k=laser+safety+glasses+450+nm&i=tools&ref=nb_sb_noss

this is the one I got: https://www.amazon.com/gp/product/B07DC6GYW8/ref=ppx_od_dt_b_asin_title_s00?ie=UTF8&psc=1

I chose it because the optical density at the relevant wavelength was way higher than the $11 version. Don’t actually know if this is needed or not, just playing it safe.

If laser seems to not be connecting here are the steps that work sometimes:

Change the COM connection to none in Lightroom

Open LaserGRBL

Press connect then confirm that the connection has been established

Enter $x to unlock laser

then disconnect LaserGRBL

In Lightburn connect through the COM3 port again

I have tried sending the gcodes that I saved from when it was all working via LB to the laser, but that didn’t work. I have also had to reinstall LaserGRBL and the custom buttons, which helped partially.

The good news is that I’ve gotten a lot faster at re-installing software. OK for the now but would prefer better stability or faster recoveries… Totally open to suggestions…

from an earlier post, with resolution:

I also liked the suggestion of copying the gcode from the laser but I’m not clear on how I reload it should the need arise.----> copy all the code from the saved .txt file, then paste the whole thing into the field for gcodes using the console tab in LB.

I’ve also had it work where just deselecting the com port in LB and then re-selecting it restores connection. Still, I also had to hit the reset button on the laser when I did something it didn’t like and hung.

Oh, that’s good enough to copy and post here.

Being a DSP user I didn’t know about these.

Attribution for this to http://domoticx.com/:

ERROR LIST

“error:1” : _(“G-code words consist of a letter and a value. Letter was not found.”),

“error:2” : _(“Numeric value format is not valid or missing an expected value.”),

“error:3” : _(“Grbl ‘$’ system command was not recognized or supported.”),

“error:4” : _(“Negative value received for an expected positive value.”),

“error:5” : _(“Homing cycle is not enabled via settings.”),

“error:6” : _(“Minimum step pulse time must be greater than 3usec”),

“error:7” : _(“EEPROM read failed. Reset and restored to default values.”),

“error:8” : _(“Grbl ‘$’ command cannot be used unless Grbl is IDLE. Ensures smooth operation during a job.”),

“error:9” : _(“G-code locked out during alarm or jog state”),

“error:10” : _(“Soft limits cannot be enabled without homing also enabled.”),

“error:11” : _(“Max characters per line exceeded. Line was not processed and executed.”),

“error:12” : _(“(Compile Option) Grbl ‘$’ setting value exceeds the maximum step rate supported.”),

“error:13” : _(“Safety door detected as opened and door state initiated.”),

“error:14” : _(“(Grbl-Mega Only) Build info or startup line exceeded EEPROM line length limit.”),

“error:15” : _(“Jog target exceeds machine travel. Command ignored.”),

“error:16” : _(“Jog command with no ‘=’ or contains prohibited g-code.”),

“error:20” : _(“Unsupported or invalid g-code command found in block.”),

“error:21” : _(“More than one g-code command from same modal group found in block.”),

“error:22” : _(“Feed rate has not yet been set or is undefined.”),

“error:23” : _(“G-code command in block requires an integer value.”),

“error:24” : _(“Two G-code commands that both require the use of the XYZ axis words were detected in the block.”),

“error:25” : _(“A G-code word was repeated in the block.”),

“error:26” : _(“A G-code command implicitly or explicitly requires XYZ axis words in the block, but none were detected.”),

“error:27” : _(“N line number value is not within the valid range of 1 – 9,999,999.”),

“error:28” : _(“A G-code command was sent, but is missing some required P or L value words in the line.”),

“error:29” : _(“Grbl supports six work coordinate systems G54-G59. G59.1, G59.2, and G59.3 are not supported.”),

“error:30” : _(“The G53 G-code command requires either a G0 seek or G1 feed motion mode to be active. A different motion was active.”),

“error:31” : _(“There are unused axis words in the block and G80 motion mode cancel is active.”),

“error:32” : _(“A G2 or G3 arc was commanded but there are no XYZ axis words in the selected plane to trace the arc.”),

“error:33” : _(“The motion command has an invalid target. G2, G3, and G38.2 generates this error, if the arc is impossible to generate or if the probe target is the current position.”),

“error:34” : _(“A G2 or G3 arc, traced with the radius definition, had a mathematical error when computing the arc geometry. Try either breaking up the arc into semi-circles or quadrants, or redefine them with the arc offset definition.”),

“error:35” : _(“A G2 or G3 arc, traced with the offset definition, is missing the IJK offset word in the selected plane to trace the arc.”),

“error:36” : _(“There are unused, leftover G-code words that aren’t used by any command in the block.”),

“error:37” : _(“The G43.1 dynamic tool length offset command cannot apply an offset to an axis other than its configured axis. The Grbl default axis is the Z-axis.”),

“error:38” : _(“An invalid tool number sent to the parser”),

“ALARM:1” : _(“Hard limit triggered. Machine position is likely lost due to sudden and immediate halt. Re-homing is highly recommended.”),

“ALARM:2” : _(“G-code motion target exceeds machine travel. Machine position safely retained. Alarm may be unlocked.”),

“ALARM:3” : _(“Reset while in motion. Grbl cannot guarantee position. Lost steps are likely. Re-homing is highly recommended.”),

“ALARM:4” : _(“Probe fail. The probe is not in the expected initial state before starting probe cycle, where G38.2 and G38.3 is not triggered and G38.4 and G38.5 is triggered.”),

“ALARM:5” : _(“Probe fail. Probe did not contact the workpiece within the programmed travel for G38.2 and G38.4.”),

“ALARM:6” : _(“Homing fail. Reset during active homing cycle.”),

“ALARM:7” : _(“Homing fail. Safety door was opened during active homing cycle.”),

“ALARM:8” : _(“Homing fail. Cycle failed to clear limit switch when pulling off. Try increasing pull-off setting or check wiring.”),

“ALARM:9” : _(“Homing fail. Could not find limit switch within search distance. Defined as 1.5 * max_travel on search and 5 * pulloff on locate phases.”),

“Hold:0” : _(“Hold complete. Ready to resume.”),

“Hold:1” : _(“Hold in-progress. Reset will throw an alarm.”),

“Door:0” : _(“Door closed. Ready to resume.”),

“Door:1” : _(“Machine stopped. Door still ajar. Can’t resume until closed.”),

“Door:2” : _(“Door opened. Hold (or parking retract) in-progress. Reset will throw an alarm.”),

“Door:3” : _(“Door closed and resuming. Restoring from park, if applicable. Reset will throw an alarm.”),

My learnings from getting the Ortur laser up and running:

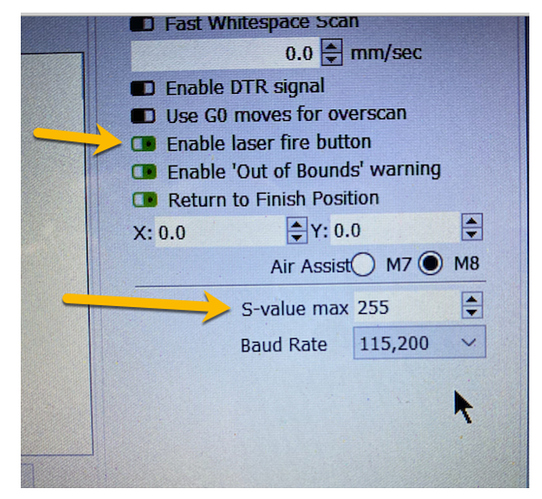

- The default setting in Lightburn for the $30, or “S,” aka “Max spindle speed,” was set to 255 when it should’ve been at 1000 which left the laser not turning on fully. This change can be made as shown in the attached images LB:\Edit\device settings

-

In order to test focus of the laser, you need to have it on at 1% power while it’s staying one place . This can be enabled by use of the FIRE button which is set from the LB:\Edit\device settings menu of LightBurn. The key is that you then have to exit LB and reopen it to have the change take effect. The button is only available from the Move tab. You also have control over whether that menu was displayed, so make sure that is enabled. UPDATE 3/28 To more accurately FRAME the work, press FIRE to light up the laser, then hold down the SHIFT key while clicking either FRAME button

-

Use absolute coordinates. Mine was set for something else so it kept bumping into the limits and then shutting down the whole job with a printing with an error.

-

The DEVICE button in Lightburn can be right-clicked to reset the laser. This is very handy when you end up with an error code.

-

In the Console tab you can enter a command or use $$ which shows you all the settings as a way of verifying that the laser in the LightBurn are actively communicating

-

Focus only gives you a bar, not a point, so it’s not quite as sharp as the big lasers in the shop. Focus is largely achieved by loosening the bracket and sliding the laser body up and down, but the range of motion is quite limited, about an inch. It looks to me as though that piece could be 3-D printed and swapped out to give a much larger range of motion and I think that would be an excellent project for a 3-D enabled user. If anyone happens to have a 3-D printer at home… It would be a much simpler fix than building a box with sliding rails etc.

-

Using the tape makes a huge difference in the crispness of the engraving

Tomorrow morning I’m heading to the garage to apply your learnings!

Will you be able to attend Saturday’s Video SIG at 10:00?

I’d love for you to chime in with learnings and participate in the Q&A.

Additional thoughts on setup of the Ortur laser:

If using Windows, be sure to install the updated COM drivers

2. When installing updated firmware, the files cannot be installed directly from the zip file. It must be extracted first and then copied into the folder opened by the laser.

3. Smoke generation can be a real problem since you probably won’t have fan-assisted venting to the outside with this small machine. At least wear a particulate dust mask, keep the garage door open if available, use a fan to disperse the smoke, and keep the door to the house closed or you’ll stink it up.

4. Obtain a second set of laser goggles in case you have a visitor

5. Coordinates and origins looks like it will take some time to configure and master. Perhaps, in retrospect, it will be obvious.

https://github.com/LightBurnSoftware/Documentation/blob/master/CommonGrblSetups.md

Updated use of FIRE button: To more accurately FRAME the work, press FIRE to light up the laser, then hold down the SHIFT key while clicking either FRAME button

Another successful set-up!

Larry is now cranking out results from his MacBook Pro!