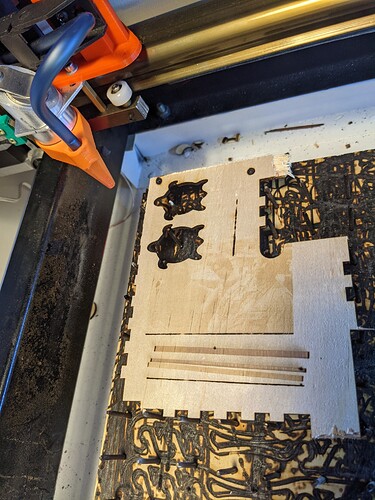

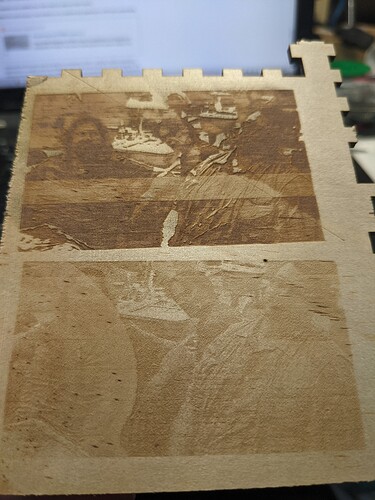

LinuxCNC is not CAM software, it is the motion controller and gcode parser part of the picture. And I still use Lightburn but don’t use LightBurn for the GCode sending part. LightBurn is the CAM just as on the 3D printer Prusa Slicer is the CAM for 3D printing. Both LightBurn and Prusa Slicer have builtin GCode senders which stream the GCode they generated to the firmware on the machine which parses the GCode and figures out how to interpret that to move motors and turns things on/off. LinuxCNC does this stuff in realtime with realtime user control. ie when you say stop it stops instead of stopping after the commands in the buffer finish. Tough to explain it all but will try an overview.

LinuxCNC has always been a complete motion control system for machines of all types it just used to cost so darn much and take up so much space to use a real motion control system for DIY projects like RepRap and home CNC. So RepRap had to comprimise with a low cost low capability control hardware and firmware(reprap, marlin, sailfish, etc ). They all were created because it was too expensive for the hardware to run a full motion controller software. They are all slowling growing up to run on 32bit processors and each are adding more GCode support( G2,G3 for example ). But now the opposite is true, ie the hardware with the performance needed to run the high-end motion controller software has become so inexpensive that that for under $100 it’s doable.

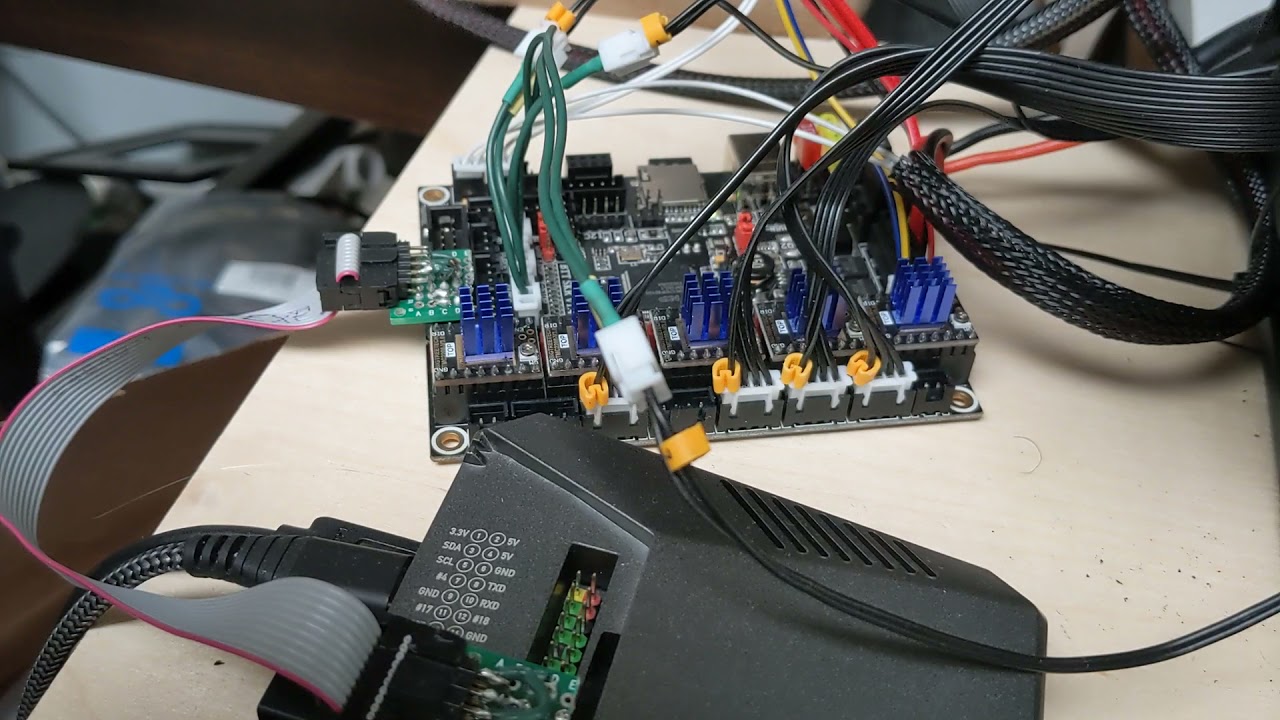

And I’m leveraging the fact that these 32bit ARM controllers for 3D printing( SKR v1.4 / MSK Sbase v1.3 / Smoothie / Cohesion / etc ) are so popular they are inexpensive and capable of doing the realtime stepper motor, encoder, etc control required for the motion controller.

Also, the use of stepper motors has limited capabilities because of edge cases when steps are missed by the motors due to periodic load peeks. LinuxCNC was designed for use with encoders and now inexpensive encoders like the AS5047 are under $20 and can be mounted to the back of a stepper motor. Had Carbide3D been using a cheap encoder on their belted Z axis you guys would never have known there was any position slipping. But they had to throw a hardware solution at it for hundreds of dollars.

Don’t get me wrong, LinuxCNC is not for everyone just as Linux was not for everyone until someone starting making it pretty and easier to use. People have no ideas they are using Linux when they use a Tivo, or an Android phone, etc because someone made the UI easier for them to use.

Tormach is one CNC vendor who uses LinuxCNC and created their own UI. And LinuxCNC is designed with capabilities to do almost click/drag UI building and there are lots of UI options already available to use with it. And if you look around, there are lots of 32bit controllers and firmware being used on 3D printers, lasers and CNC/routers so wouldn’t it be cool if there really was ’ One ring to rule them all, one ring to find them , One ring to bring them all, and in the darkness bind them’?