My answers, responses, get long. And often generate opposing opinions. I have made a number of display cases and here are some comments.

Plywood has a rough edge you need to seal with some sort of veneer during the construction process. I prefer heat sensitive glue-on and Rockler, the big box stores, and Amazon may have numerous wood types in stock – oak, pine, maple, etc. Rockler has the gizmo to trim it to width. Trimming to width is occasionally grain sensitive, one way of trimming may be good, the other way may pull material from the finish area. Until I bought a small tile roller I was using a large mechanic’s socket to press the veneer on.

Examples:

This does not appear to need heat, I have not used it.

https://www.homedepot.com/p/EDGEMATE-13-16-in-x-25-ft-Birch-Edge-Tape-657608/202843396

A sheet of 48”(x)x96”(y)x1/2”(z) plywood may not be ½” thick. In most cases, big box stores are doing a better job at labeling wood products. However, there is always expansion and contraction events with any wood product that change those values. Manufactured wood products are more stable in dimensions than natural wood. Working with plywood cutting the vertical sides requires sealing the ends and that changes the XY dimensions slightly, just enough to throw fine measurements off. Therefore, plan measurements may need to be adjusted during construction.

Z or thickness is not exact – as stated, ½”, 0.50” may be 15/32” or 0.46875”. And those values are not always exact. When working with materials from two different batches from the same manufacturer you can expect variances. When cutting the shelf slots this comes into play. I have Dado blades for the “new standard” thicknesses of plywood as well as router bits to those “undersized” dimensional values. While close, this is a triple check issue.

While plywood gives you much better control over XY dimensions, you sacrifice the Z factor. Planing plywood removes its very thin finished veneer unless you purchase some very expense “thick finish veneer.” With that said, I prefer plywood as natural wood increases the risk of post assembly warping.

I prefer to use pins to hold my display cases together. I have yet to find a good filler to cover nails and screws which does not stand out like a sore thumb when finish is applied. I would imagine a number of contributors will tell us their product usage. ½” thick plywood allows me to use 1/8” and 3/16” pins without risk. ¼” pins need to be right on or risk a breakout. Pins have grains you can get pretty close to match the base material during insertion. A flush or flat cutoff saw is a handy tool to have.

https://www.homedepot.com/p/Stanley-4-75-in-Pull-Saw-with-Plastic-Handle-20-331/100654914

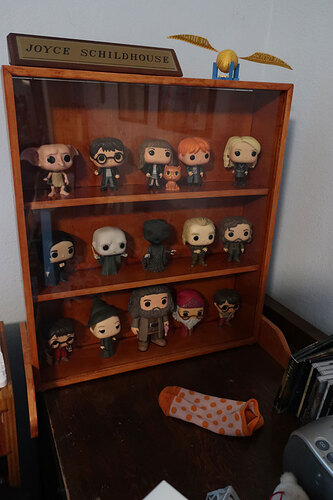

The photo is the only display case I can quickly find in the house. Most were made for stores and classrooms. The fun is getting the back inside to hold the display case true to square.

Plywood is my preferred material. Good plans at the start and figure out where veneer goes and then verify dimensions as you go. I use my CNC machine for much of the verticals and my table saw for the shelves and backs.

This case has “stabilizers” as it was going into a classroom.

I cut my acrylic sheets on my bandsaw at the slowest speed setting to preclude heating and melting.

Thanks,

Rex