This is the text of the attached PDF.

I was using the Open Sign tutorial and made the following notes, provided so you can see my process,

Set the material size and XY Datum at the center for the design work,

Create the border with the center at X 0 and Y 0,

Create the second border,

To center a hole, hover over the first line, then hover over the second line, then move to the approximate center between those two points and Vectric will show a + sign,

To scale the size, you can hold Shift and then drag with the mouse,

Check the Material Set Up and move the reference to the lower left corner,

Make sure there is no offset,

Select the outer edge of the pocket, drag to capture all of the text with the left mouse button down,

Select V Carve Tool Path,

Define cutting depth,

Select Flat Depth of something like 0.20,

Select the V Bit tool for the first tool,

Select the Use Clearance Tool,

Select the 0.25 End Mill as a clearance tool,

Select the outer edge, select Profile and then the V Bit tool on the outside,

Select the outer edge, select Profile, and the 0.25 End Mill with a 0.20 offset outside,

Use Plunge,

Add tabs,

This is the exported image from VectricPro V10. It disagrees with the results.

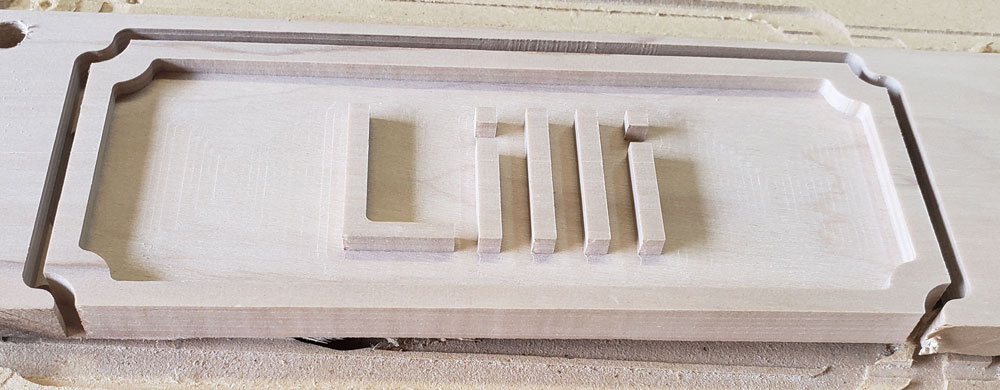

This is an attempt in VectricPro V10 with Carbide Motion on my Shapeoko XXL.

This is the V-Carve Engraving Toolpath set up. The material is 3 ½” high by 9” wide by 0.525” thick. The desired cut is 0.200.

This is the first pocket pass with a 0.250 End Mill, Tool 201 in the Shapeoko tool inventory. The cut is pretty close to 0.200”, the value set in the tool path.

This is the V Carve pass with the Shapeoko Tool 301, ½” 90 degree V-bit. The cut is set to 0.200” and the actual cut is close to 0.400”. The surprises include the depth, the steps at the bases of the letters, and the exterior dog bone issues on the corners.

This is the exterior V Bit cut, set to 0.200” and cutting to close to 0.400”, which matches the inside V carve depth. It should leave a face surface, as shown in the Vectric image.

Final product, out of the work. The outline of the letters is not smooth, the bottom is not flat, the depth is beyond the 0.200” set in the toolpaths, and the dog bone issues on the issue V Carve.

A repeat of the Vectric image for comparison.

And, Vectric keeps saying that the final profile cut is going through the material while the material thickness is set to 0.525” and the cut depth is set to 0.525” as well. A bit frustrated. What setting, what process, is wrong?

Thanks,

Rex A Schildhouse

Lieutenant Commander, United States Navy, Retired and tired

SDFWA-Wyatt Trial 2 Comments-Rex A Schildhouse-2020-05-05.pdf (765.5 KB)