When we were doing the Fusion 360 sessions and I was being initiated into the world of CNC, we made a parametric fruit bowl. It was a fun little exercise and good for learning various techniques on both CAD and CNC. It also generated some feedback and observations:

- Two-sided machining for the blind dowel holes added complication and could be avoided by insetting “tracks” for overlapping layers.

- Geometry was a bit restricted by the need for each tier to fit inside the previous one.

- The result looked quite “geometric”.

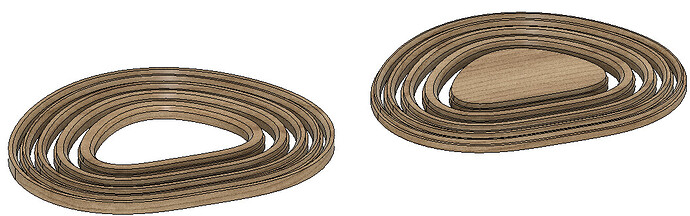

- The open sides weren’t to many people’s taste, though the idea of allowing air to surround the fruit was a good one.

This led me to think that I could come up with a more eye-pleasing design that would address these items and perhaps also be a good exercise for learning how to use Fusion 360 for CNC in some more innovative ways. Also, a OneFinity CNC lives in my shop now that I’ve moved to Vancouver Island and can’t access the SDFWA shop.

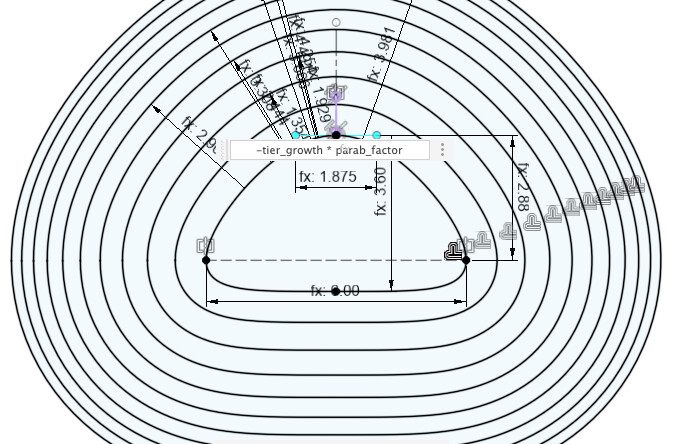

Those who attended the Design SIG meetings will expect (correctly) that the design is very parametric. Parameters not only can be altered for different sizes, but the shape and profile of the bowl are driven parametrically. This not only addresses my personal need to overly complicate designs, but is also a demonstration of multiple ways to use parameters. To allow a continuous wall, there are 2 “sets” of tiers cut out so that alternating rings can overlap. The rings are inset into each other, so it can all be machined from one side, the rings are self-aligning and easy to glue up. I’ve used local maple for these bowls, though one could even use 2 different pieces of wood and have the rings alternating in color.

If there is interest in making one, I could make a video to share how it is done and how to use the file and parameters.